What is a Mining Lighting Transformer?

LED LIGHTING GROUP

What is a Mining Lighting Transformer?

A Mining Lighting Transformer is a special type of transformer designed specifically to power the lighting systems in mines (including coal and non-coal mines). Its core task is to provide a safe, reliable, and stable low voltage to operate the underground lighting equipment.

Key Characteristics and Design Purpose:

Voltage Conversion: It typically converts the higher voltage of the mine's power grid (e.g., 660V, 1140V) to a Safety Extra-Low Voltage (SELV) required by the lighting system, most commonly 127V. This voltage level is considered relatively safe in damp, conductive environments, significantly reducing the risk of electric shock.

Safety Isolation: It is an Isolation Transformer. Its secondary winding (output side) is electrically isolated from the earth and the primary winding (input side). This means that even if a miner simultaneously touches one line of the 127V output and the ground, a closed circuit will not be formed, thus preventing electric shock.

Dedicated Load: Its design purpose is primarily to supply lighting loads (e.g., incandescent lamps, LED lights). The load characteristics are relatively stable, and the capacity is usually small (from a few kVA to several tens of kVA).

Basic Protection: Although it also possesses certain mining protection features (like moisture resistance, shock resistance), its primary focus is on providing a safe power source, not necessarily handling high concentrations of explosive gases.

In simple terms, a Mining Lighting Transformer is the "safe heart" of the mine's lighting circuit; its primary task is "shock prevention."

What is an Explosion-Proof Mining Transformer?

An Explosion-Proof Mining Transformer is a broader concept referring to all mining transformers designed to prevent the ignition of surrounding explosive gas mixtures and can be used in explosive hazardous environments. It is not just a power source for lighting systems but is a core component of the entire underground power system.

Key Characteristics and Design Purpose:

Explosion-Proof Construction: This is its core feature. It employs special explosion-proof enclosures ("Types of Protection"), for example:

Flameproof Enclosure ('Ex d'): The enclosure can withstand an internal explosion and prevent the internal flame from propagating to the external atmosphere, thus not igniting the surrounding gas.

Increased Safety ('Ex e'): Additional measures are applied to the transformer and terminals that do not produce arcs, sparks, or dangerous hot surfaces during normal operation, further enhancing safety.

High Power Capacity: The capacity is usually large (from tens of kVA to several thousand kVA), used to power various high-power equipment underground, such as shearers, roadheaders, conveyor belts, water pumps, and auxiliary fans.

Diverse Output Voltages: Its output voltage varies according to the connected equipment's needs, which can be medium voltage levels like 660V, 1140V, 3300V, etc. It may also include a 127V winding for lighting, but this is not its primary function.

Comprehensive Protection: Besides being explosion-proof, it must also have a robust mechanical structure, excellent moisture resistance, corrosion resistance, and shock resistance to adapt to the harsh underground working environment.

In simple terms, an Explosion-Proof Mining Transformer is the "explosion-proof power core" of the mine's motive power system; its primary task is "explosion prevention" and providing power for various equipment.

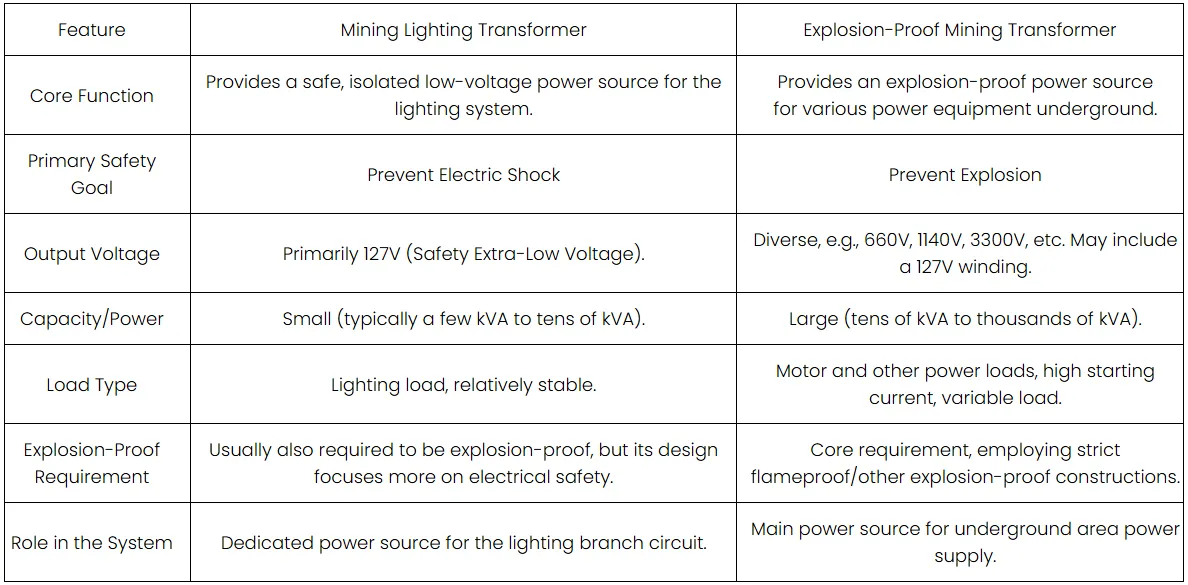

Key Differences Between the Two

For a more intuitive comparison, please refer to the table below:

(1).webp?x-oss-process=image/resize)