Compact Substation

LED LIGHTING GROUP

Compact Substation

◆ Definition

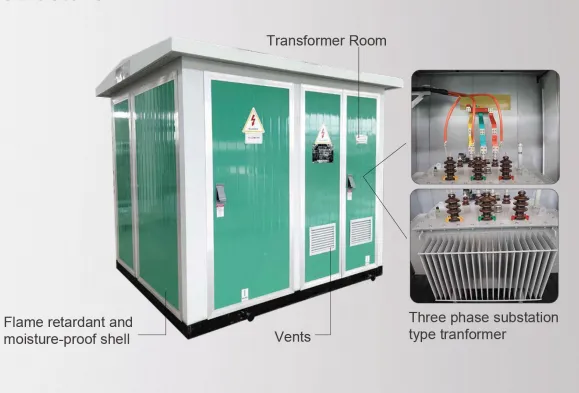

A COMPACT TRANSFORMERSUBSTATION canbe explained as agroup of electrical equipment that is assembled on a trailer or platform.To ensure that a compact substation is capable of fully energizing uponits delivery to the required site, it is integrated and thoroughly tested in a factory environment.

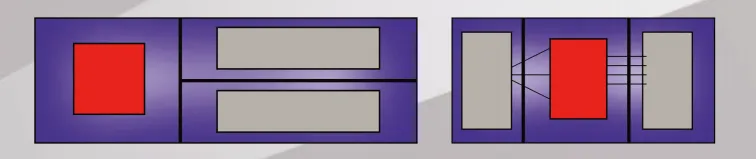

◆ Compact transformer substation layout

◆ Structure

◆ Technical Data Of YB Pre-installed Substation

| Ltem | Unit | Date | |

| HV | Rated Frequency | Hz | 50 |

| Rated Voltage | kV | 6 10 35 | |

| Max Working Voltage | kV | 6.9 11.5 40.5 | |

| Industrial Frequency Voltage-resisting Time / Isolation Ballistic Voltage-resisting | kV | 32/36 42/48 95/118 | |

| Thunderand Lighting Ballistic Voltage-resisting Time / isolation SectionalPort | kV | 60/70 75/85 185/215 | |

| Rated Current | A | 400 630 | |

| Rated Brief-period Current-resisting | kA | 12.5(2s) 16(2s) 20(2s) | |

| Rated Crest Value Current-resisting | kA | 32.5 40 50 | |

| LV | Rated Voltage | V | 380 220 |

| Rated Current Of Major Return Circuit | A | 100-3200 | |

| Rated short-circuit Current-resisting | kA | 15 30 50 | |

| Rated Crest Value Current-resisting | kA | 30 63 110 | |

| Branch Circuit | A | 10-800 | |

| Quantity Of Branch | line | 1-12 | |

| Compensation Circuit | kVAR | 0-360 | |

| Transforming | Rated Capacity | kVA | 50-2000 |

| Short-circuit Impedance | % | 4 6 | |

| Scope Of Branch Connection | ±2×2.5% ±5% | ||

| Vector Group | Yyn0 Dyn11 |

Scalable Compact Substations for Industrial Use

Scalable, Efficient Power Distribution Solutions

A compact substation is an innovative, space-saving solution designed to optimize power distribution in urban, industrial, and remote environments. Integrating key components like transformers, switchgear, and protection systems into a single, modular structure, these substations deliver reliable, high-performance power transmission with minimal footprint. Engineered to meet international standards (IEC, IEEE), our compact substations combine safety, efficiency, and adaptability for diverse applications.

Core Features & Benefits

Space-Efficient Design

Modular architecture reduces physical size by up to 60% compared to traditional substations, making installation feasible in constrained spaces like urban corridors, industrial plants, or remote communities. Pre-assembled units minimize on-site construction time.

High Performance & Reliability

Equipped with oil-immersed or dry-type transformers, vacuum circuit breakers, and SF6 gas-insulated switchgear (GIS), these substations ensure efficient power regulation (11kV to 33kV) and protection against faults. Robust insulation and cooling systems enhance durability in harsh climates.

Smart Automation & Monitoring

Optional IoT-enabled systems provide real-time data on voltage, current, temperature, and fault detection. Remote control capabilities via SCADA integrate with smart grid networks, enabling predictive maintenance and reducing downtime.

Quick Deployment & Scalability

Factory-assembled and tested units can be installed in days, accelerating project timelines. Scalable designs allow capacity upgrades (up to 50 MVA) without replacing the entire system, supporting long-term energy growth.

Eco-Friendly & Cost-Effective

Low noise operation (<65 dB) and recyclable materials comply with environmental regulations. Energy-efficient designs reduce power losses by up to 25%, lowering operational costs.

Applications

Urban Infrastructure: Substations for downtown areas, commercial hubs, and smart cities.

Industrial Zones: Stable power supply for manufacturing plants, mines, and data centers.

Remote Areas: Rapid deployment in off-grid or disaster-prone regions.

Renewable Energy: Integration with solar/wind farms for efficient grid connection.

Technical Specifications

Voltage Range: 11kV to 33kV (medium voltage).

Capacity: 5 MVA to 50 MVA.

Frequency: 50Hz/60Hz.

Cooling: Air natural (AN) or forced (AF) cooling.

Compliance: IEC 62271, IEEE 1526, and ISO 9001/14001 certified.

Quality Assurance

Rigorous testing includes dielectric strength, short-circuit withstand, and temperature rise simulations.

Certified by KEMA, DEKRA, and TÜV for safety and reliability.

Why Choose Us?

25+ Years of Expertise: Proven designs for extreme temperatures, humidity, and seismic zones.

End-to-End Services: Design, installation, and lifecycle maintenance support.

Flexible Financing: Leasing and pay-as-you-go options for budget flexibility.

Custom Solutions

Environmental Adaptations: Corrosion-resistant enclosures for coastal regions or explosion-proof designs for oil/gas sites.

Hybrid Systems: Integration of renewable energy storage (e.g., battery banks) for hybrid grids.

1. Core Materials and Winding Design

Core Materials

Amorphous Alloy Cores:

Ultra-low iron loss (70–80% lower than silicon steel) reduces energy waste, critical for compact, high-efficiency designs.

High permeability and near-zero magnetostriction minimize noise, ideal for urban or residential areas.

Cold-Rolled Grain-Oriented (CRGO) Silicon Steel:

Laser-cut laminations reduce eddy current losses, achieving efficiency levels up to 98.5% in limited spaces.

High magnetic flux density supports compact high-voltage (11kV–33kV) applications.

Winding Design

Foil Windings with Oil-Flow Cooling:

Copper/aluminum foil windings reduce leakage flux and short-circuit forces. Integrated oil channels enhance heat dissipation in confined layouts.

Interleaved layers minimize inter-turn voltage stress, improving short-circuit resilience (up to 50 kA asymmetrical faults).

Layered Litz Wire Windings:

Multi-strand Litz wire mitigates skin and proximity effects, reducing AC resistance for high-frequency operation (e.g., HVDC links).

Compact Disc/Winding Arrangements:

Helical or disc windings optimize space utilization, paired with graded insulation to withstand lightning impulses (≥1.2/50 μs).

2. Insulation Systems

Oil-Paper Composite Insulation:

Cellulose paper impregnated with ester fluids provides dielectric strength up to 300 kV BIL, ideal for compact high-voltage compartments.

Resistant to thermal cycling (−40°C to +140°C) and partial discharge.

Epoxy Resin Casting (Dry-Type):

Vacuum-pressure impregnation (VPI) with Class H epoxy resins ensures fire resistance (IEC 60335) and moisture tolerance in sealed environments.

Nano-Enhanced Insulation:

Silica-filled epoxy composites improve partial discharge resistance by 40%, extending lifespan in humid or polluted urban areas.

3. Thermal Management

Oil-Natural Air-Cooling (ONAN):

Passive cooling via radiators and natural convection for continuous operation in compact footprints (e.g., 100kVA–500kVA units).

Forced Air Cooling (OFAF):

Temperature-controlled fans enhance heat dissipation, enabling 120% overload capacity for emergency scenarios.

Smart Thermal Monitoring:

Fiber-optic sensors track hotspots, triggering alarms or cooling adjustments to prevent insulation degradation.

4. Structural Design and Protection

Modular and Space-Optimized Layout

Integrated Enclosures:

Pre-fabricated, modular enclosures house transformers, switchgear, and protection systems in a single footprint, reducing installation time by 50%.

IP66/IP67 Ratings:

Hermetic sealing with EPDM gaskets and stainless-steel hardware protects against water, dust, and rodent intrusion.

Anti-Corrosion Treatment:

Hot-dip galvanized steel or aluminum enclosures with polyurethane coatings resist UV degradation and coastal salt exposure.

Safety Features

Pressure Relief Valves:

Automatically vent gases during internal faults, preventing explosive failures.

Conservator Tank Systems:

Sealed conservators minimize oxygen contact, reducing oil oxidation and sludge formation.

Surge Protection:

Integrated zinc oxide arresters (MOA) suppress lightning-induced transients (≥2.5 kA impulses).

5. Advanced Functionalities

Condition Monitoring Systems (CMS):

Embedded sensors track oil temperature, dissolved gas analysis (DGA), load levels, and partial discharge, enabling predictive maintenance via SCADA.

Smart Grid Integration:

IoT-enabled communication supports remote control, load balancing, and self-healing grid responses.

Eco-Friendly Innovations:

Bio-based insulating oils (e.g., ester fluids) with high biodegradability (OECD 301B compliant) and lower flammability.

Key Applications and Future Trends

Urban Distribution:

High-density units (500kVA–1 MVA) power city substations, renewable microgrids, and EV charging stations.

Renewable Energy Integration:

Compact designs for wind/solar farms and hybrid AC/DC microgrids.

Future Advancements:

Solid-State Transformers (SSTs): Enable DC-DC conversion and grid flexibility for decentralized systems.

Self-Healing Insulation: Nanocomposite materials autonomously repair minor dielectric defects.

Summary

Compact Substations excel through low-loss amorphous cores, space-saving modular designs, and multi-layered safety systems. Their blend of efficiency, scalability, and resilience makes them indispensable for modern urban and industrial grids, while innovations like solid-state technology and smart monitoring drive grid intelligence and sustainability.

(1).webp?x-oss-process=image/resize)