Dry Type Transformer

LED LIGHTING GROUP

Dry Type Transformer

◆ Definition

Cast resin dry type transformer is a type of SC(B) dry transformer with epoxyresin, which is a widely used in many fields. Its winding surface consists ofhigh-quality protective material that forms the cover.Even in harsh environments such as dust and humidity, it will not affect the castinsulating dry-type transformer; the process characteristic of resin casting is thatit must rely on molds and use special casting equipment to cast the coil in avacuum state. The epoxy resin used is an insulating glue, so it is also called anepoxy cast resin dry type transformer

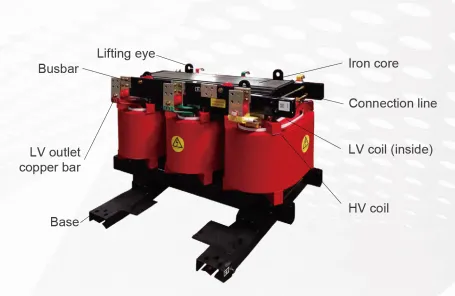

◆ Structure

◆ Technical Specification

①Type14of6kV,10kVdry-typeno-excitationdistributiontransformers TechnicalDateSheet

| Rated Capacity (KVA) | Voltage Combination | Vector Group | No-load Loss (w) | Under different insulation heat-resisting rank load Loss(W) | No-load Current(%) | Short Circuit Impedance(%) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| HV (KV) | HV (Tapping) | LV (KV) | 130℃(B) (100℃) | 155℃(F) (120℃) | 180℃(H) (145℃) | |||||

| 30 | 6 6.3 6.6 10 10.5 11 |

±5% ±2x2.5% |

0.4 |

Dyn11 Yyn0 |

130 | 605 | 640 | 685 | 2.00 | 4 |

| 50 | 185 | 845 | 900 | 965 | 2.00 | |||||

| 80 | 250 | 1160 | 1240 | 1330 | 1.50 | |||||

| 100 | 270 | 1330 | 1415 | 1520 | 1.50 | |||||

| 125 | 320 | 1585 | 1665 | 1780 | 1.30 | |||||

| 160 | 365 | 1800 | 1915 | 2050 | 1.30 | |||||

| 200 | 420 | 2135 | 2275 | 2440 | 1.10 | |||||

| 250 | 490 | 2330 | 2485 | 2665 | 1.10 | |||||

| 315 | 600 | 2945 | 3125 | 3355 | 1.00 | |||||

| 400 | 665 | 3375 | 3590 | 3850 | 1.00 | |||||

| 500 | 790 | 4170 | 4390 | 4760 | 1.00 | |||||

| 630 | 910 | 4930 | 5290 | 5605 | 0.85 | |||||

| 800 | 865 | 5050 | 5365 | 5710 | 0.85 | |||||

| 1000 | 1025 | 5895 | 6885 | 7315 | 0.85 | |||||

| 1250 | 1420 | 8190 | 8720 | 9350 | 0.85 | 6 |

||||

| 1600 | 1665 | 9945 | 10550 | 11320 | 0.85 | |||||

| 2000 | 2075 | 12240 | 13005 | 14005 | 0.70 | |||||

| 2500 | 2450 | 14535 | 15445 | 16605 | 0.70 | |||||

②20kV the level SC(B)10 series no-excitation dry type distribution transformer performance parameter

| Rated Capacity (KVA) | Voltage Combination | Vector Group | No-load Loss (w) | Under different insulation heat-resisting rank load Loss(W) | No-load Current(%) | Short Circuit Impedance(%) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| HV (KV) | HV (Tapping) | LV (KV) | 130℃(B) (100℃) | 155℃(F) (120℃) | 180℃(H) (145℃) | |||||

| 50 | 20 22 24 |

±2x2.5% ±5% |

0.4 |

Dyn11 Yyn0 |

340 | 1160 | 1230 | 1310 | 2.00 | 6 |

| 100 | 540 | 1870 | 1990 | 2130 | 1.80 | |||||

| 160 | 670 | 2330 | 2470 | 2640 | 1.60 | |||||

| 200 | 730 | 2770 | 2940 | 3140 | 1.60 | |||||

| 250 | 840 | 3220 | 3420 | 3660 | 1.30 | |||||

| 315 | 970 | 3850 | 4080 | 4360 | 1.30 | |||||

| 400 | 1150 | 4650 | 4840 | 5180 | 1.10 | |||||

| 500 | 1350 | 5460 | 5790 | 6190 | 1.10 | |||||

| 630 | 1530 | 6450 | 6840 | 7320 | 1.00 | |||||

| 800 | 1750 | 7790 | 8260 | 8840 | 1.00 | |||||

| 1000 | 2070 | 9220 | 9780 | 10400 | 0.85 | |||||

| 1250 | 2380 | 10800 | 11500 | 12300 | 0.85 | |||||

| 1600 | 2790 | 13000 | 13800 | 14800 | 0.85 | |||||

| 2000 | 3240 | 15400 | 16300 | 17500 | 0.70 | |||||

| 2500 | 3870 | 18200 | 19300 | 20700 | 0.70 | |||||

| 2000 | 3240 | 16800 | 17800 | 19100 | 0.70 | 8 | ||||

| 2500 | 3870 | 20000 | 21200 | 22700 | 0.70 | |||||

Note:ln the table arranges the load loses for the parenyhesis refers to the temperature (to see the stipulation of GB1094.11) under value

③35kV the level SC(B)10 series no-excitation dry type distribution transformer performance parameter

| Rated Capacity (KVA) | Voltage Combination | Vector Group | No-load Loss (w) | Under different insulation heat-resisting rank load Loss(W) | No-load Current(%) | Short Circuit Impedance(%) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| HV (KV) | HV (Tapping) | LV (KV) | 130℃(B) (100℃) | 155℃(F) (120℃) | 180℃(H) (145℃) | |||||

| 50 | 35 36 37 38.5 |

±2×1.25% ±5% |

0.4 |

Dyn11 Yyn0 |

450 | 1340 | 1420 | 1520 | 2.30 | 6 |

| 100 | 630 | 1970 | 2090 | 2230 | 2.00 | |||||

| 160 | 790 | 2650 | 2810 | 3000 | 1.50 | |||||

| 200 | 880 | 3130 | 3320 | 3550 | 1.50 | |||||

| 250 | 990 | 3580 | 3800 | 4060 | 1.30 | |||||

| 315 | 1170 | 4250 | 4510 | 4820 | 1.30 | |||||

| 400 | 1370 | 5100 | 5410 | 5790 | 1.10 | |||||

| 500 | 1620 | 6270 | 6550 | 7110 | 1.10 | |||||

| 630 | 1860 | 7250 | 7690 | 8230 | 1.00 | |||||

| 800 | 2160 | 8600 | 9120 | 9760 | 1.00 | |||||

| 1000 | 2430 | 9860 | 10400 | 11100 | 0.75 | |||||

| 1250 | 2830 | 12000 | 12700 | 13600 | 0.75 | |||||

| 1600 | 3240 | 14600 | 15400 | 16500 | 0.75 | |||||

| 2000 | 3820 | 17200 | 18200 | 19500 | 0.75 | |||||

| 2500 | 4450 | 20600 | 21800 | 23300 | 0.75 | |||||

Note:ln the table arranges the load loses for the parenyhesis refers to the temperature (to see the stipulation of GB1094.11) under value

Dry Type Transformer

A dry-type transformer is a cutting-edge electrical device engineered for safe, reliable, and efficient power distribution in diverse applications. Unlike oil-immersed transformers, dry-type units use solid or gas insulation (e.g., epoxy resin, cast resin, or SF6 gas) instead of mineral oil, eliminating fire risks and environmental contamination. Ideal for indoor installations, urban environments, and sensitive areas, these transformers combine sustainability, low maintenance, and high performance.

Core Features & Benefits

Fireproof & Eco-Friendly Design

With no flammable oil, dry-type transformers meet stringent fire safety standards (IEC 61558) and are ideal for hospitals, data centers, and residential buildings. Recyclable materials and zero oil leakage ensure environmental compliance.

High Efficiency & Energy Savings

Advanced core materials (amorphous alloy or silicon steel) and optimized winding designs reduce energy losses by up to 30%, achieving efficiency levels ≥98% (IEC 61378 certified). Suitable for continuous operation with minimal heat generation.

Low Maintenance & Longevity

Solid insulation systems resist moisture, dust, and chemical contaminants, reducing maintenance needs. Robust construction withstands harsh conditions, extending service life in industrial or coastal environments.

Compact & Space-Saving

Modular designs and compact footprints simplify installation in urban substations, commercial buildings, or renewable energy sites. Available in voltages from 380V to 36kV and capacities up to 5 MVA.

Smart Monitoring & Safety

Optional IoT sensors monitor temperature, voltage, and load in real time, enabling predictive maintenance. Built-in protection systems (e.g., thermal relays, Buchholz alarms) prevent faults and ensure safe operation.

Applications

Urban Infrastructure: Safe power distribution in high-density areas, malls, and subway systems.

Industrial Use: Stable supply for manufacturing plants, mining operations, and chemical industries.

Renewable Energy: Integration with solar/wind farms for efficient grid connection.

Commercial Buildings: HVAC systems, elevators, and lighting networks.

Technical Specifications

Voltage Range: 380V to 36kV (medium voltage).

Capacity: 50 kVA to 5,000 kVA.

Cooling Types: Air Natural (AN) or Air Forced (AF).

Insulation Class: H-class (180°C) for high thermal resilience.

Frequency: 50Hz/60Hz.

Quality Assurance

Rigorous testing includes impulse voltage, load loss, and temperature rise simulations.

Certified by IEC, IEEE, ISO 9001 (quality), and ISO 14001 (environment).

Why Choose Us?

30+ Years of Expertise: Proven designs for extreme temperatures, humidity, and seismic zones.

Global Support: Localized engineering teams and 24/7 technical assistance.

Cost-Effective Solutions: Scalable designs with flexible financing options.

Custom Solutions

Fire-Resistant & Explosion-Proof Models: For oil/gas facilities or hazardous areas.

Eco-Friendly Designs: Low-noise (<65 dB) and lead-free configurations.

Hybrid Systems: Combined with energy storage for smart grid applications.

1. Core Materials and Winding Design

Core Materials

Amorphous Alloy Cores:

Ultra-low iron loss (70–80% lower than traditional silicon steel), reducing energy waste and operational costs.

High permeability and near-zero magnetostriction minimize noise and vibration, ideal for residential and commercial zones.

Cold-Rolled Grain-Oriented (CRGO) Silicon Steel:

Laser-cut or step-lapped laminations reduce eddy current losses, achieving efficiency levels up to 98% (IEC 60076 standards).

Optimized grain orientation enhances magnetic flux density for high-voltage applications (up to 33kV).

Winding Design

Foil Windings with Resin Impregnation:

Copper or aluminum foil windings reduce leakage flux and short-circuit forces. Epoxy resin encapsulation enhances mechanical strength and thermal conductivity.

Interleaved layers minimize inter-turn voltage stress, improving short-circuit resilience (up to 50 kA asymmetrical faults).

Layered Litz Wire Windings:

Multi-strand Litz wire mitigates skin and proximity effects, reducing AC resistance in high-frequency applications (e.g., HVDC converters).

Vacuum-Pressure Impregnation (VPI):

Coils are impregnated with high-temperature epoxy or polyester resins, ensuring moisture resistance and dielectric strength up to 200 kV BIL.

2. Insulation Systems

Epoxy Resin Casting:

Solid insulation with Class H epoxy resins provides fire resistance (UL94 V-0 certified) and withstands thermal cycling (−40°C to +155°C).

Superior partial discharge resistance, ideal for polluted or humid environments.

Nomex Paper Composite:

Aramid fiber-based insulation offers high thermal stability (up to 220°C) and dielectric strength, combined with flame-retardant properties.

Nano-Enhanced Insulation:

Silica-filled epoxy composites improve partial discharge lifetime by 40%, extending service life in harsh conditions.

3. Thermal Management

Air-Natural Cooling (AN):

Passive cooling via finned radiators or heat sinks for continuous operation at rated loads (e.g., 500kVA–1.5MVA units).

Forced Air Cooling (AF):

Temperature-controlled fans enhance heat dissipation, enabling 120–150% overload capacity for emergency scenarios.

Smart Thermal Monitoring:

Embedded temperature sensors and IoT systems trigger alarms or cooling adjustments to prevent overheating and insulation degradation.

4. Structural Design and Protection

Modular and Compact Design

Hermetic Enclosures:

IP66/IP67-rated enclosures with EPDM gaskets protect against dust, water, and rodent intrusion, suitable for outdoor or industrial environments.

Anti-Corrosion Coatings:

Hot-dip galvanized steel or aluminum enclosures with polyurethane/powder coatings resist UV degradation and coastal salt exposure.

Fire-Resistant Materials:

Non-combustible insulation and self-extinguishing resin systems meet IEC 60335 fire safety standards.

Safety Features

Pressure Relief Systems:

Automatic pressure relief vents prevent explosive failures during internal faults.

Surge Protection:

Integrated metal oxide arresters (MOA) suppress lightning-induced transients (≥2.5 kA impulses).

Grounding and Spill Prevention:

Reinforced grounding systems and sealed designs eliminate oil leakage risks, ensuring zero environmental contamination.

5. Advanced Functionalality

Condition Monitoring Systems (CMS):

Embedded sensors track winding temperature, partial discharge, and load levels, enabling predictive maintenance via SCADA or IoT platforms.

Smart Grid Integration:

IoT-enabled communication supports remote monitoring, load balancing, and self-healing grid responses.

Eco-Friendly Innovations:

Bio-based insulating resins and recyclable polymer components align with sustainability goals (e.g., RoHS and REACH compliance).

Key Applications and Future Trends

Urban and Commercial Distribution:

High-density units (500kVA–2 MVA) power cities, data centers, and EV charging stations.

Industrial and Renewable Energy:

Ideal for solar/wind farm substations, mining sites, and hazardous areas (Zone 2/22).

Future Advancements:

Solid-State Transformers (SSTs): Enable DC-DC conversion and grid flexibility for decentralized energy systems.

Self-Cooling Nanocomposites: Advanced materials autonomously dissipate heat under fault conditions.

Summary

Dry-Type Transformers excel through low-loss amorphous cores, solid insulation resilience, and smart thermal management. Their fire safety, maintenance-free operation, and eco-friendly designs make them indispensable for modern urban and industrial grids, while innovations like solid-state technology and IoT integration drive grid intelligence and sustainability.

(1).webp?x-oss-process=image/resize)