Three Phase Pad Mouted Transformer

LED LIGHTING GROUP

Three Phase Pad Mouted Transformer

◆ Definition

Three phase pad mounted transformers are designed and manufactured in compli-ance with all applicable ANSI and DOE2016 standards.All transformers are oil-filled,65°C rise, and designed for usual service conditions per IEEE C57.12.00.Ratings available are 30 through 3000 kVA with primary voltages 2.4 through 35 kV(150 kV BIL) and secondary voltages up to 600 volts. All standard tap configurationsavailable: dual voltage in most combinations, dual voltage with taps only (series con-nection only) and impedance and loss options available in most designs.

◆ Structure

◆Technical Specification

| Rated Capacity (KVA) | Voltage Combined | Vector-group | No-load Loss (W) | Load Loss at 85℃(W) | Impedance (%) | Efficiency (%) | ||

|---|---|---|---|---|---|---|---|---|

| High Voltage (V) | Tapping Ranges | Low Voltage (V) | ||||||

| 75 | 2400 4160 7200 7620 12000 12470 13200 13800 14400 24940 |

±2×2.5% | 110 120 208 240 277 347 415 480 600 690 |

YNy0 Dyn11 |

130 | 1000 | 4.0-6.3 | 99.03 |

| 150 | 200 | 1800 | 99.16 | |||||

| 225 | 350 | 3100 | 99.23 | |||||

| 300 | 430 | 3700 | 99.27 | |||||

| 500 | 600 | 5410 | 99.35 | |||||

| 750 | 880 | 7500 | 99.4 | |||||

| 1000 | 1000 | 10300 | 99.43 | |||||

| 1500 | 1400 | 14500 | 99.48 | |||||

| 2000 | 1800 | 18300 | 99.51 | |||||

| 2500 | 2300 | 23100 | 99.53 | |||||

| 3150 | ||||||||

| 3750 | ||||||||

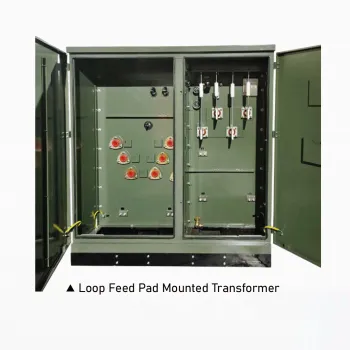

Secure Three-Phase Pad-Mounted Distribution Solutions

A three-phase pad-mounted transformer is a robust, ground-level electrical device designed to efficiently step down medium-voltage power to lower voltages for commercial, industrial, and high-density residential applications. Housed in a secure, tamper-resistant enclosure, it is a cornerstone of modern underground distribution systems, offering reliability, safety, and adaptability in urban, industrial, and utility-scale settings.

Key Features

High Power Capacity: Engineered to handle heavy loads, with superior efficiency in three-phase power distribution, making it ideal for industrial complexes and large commercial facilities.

Durable Enclosure: Constructed from corrosion-resistant steel or aluminum, the enclosure protects against environmental hazards, vandalism, and accidental contact while meeting IP55 or higher ingress protection standards.

Energy Efficiency: Advanced core materials (amorphous metal or grain-oriented silicon steel) and optimized winding designs minimize no-load and load losses, exceeding DOE 2016 and IEC 60076 efficiency benchmarks.

Low Noise & Vibration: Integrated noise-dampening materials and balanced magnetic circuits ensure quiet operation, suitable for noise-sensitive zones like hospitals and residential areas.

Safety & Reliability: Equipped with pressure-relief devices, fault indicators, arc-resistant designs, and grounded enclosures. Oil-filled units use fire-resistant or biodegradable fluids for enhanced safety.

Technical Specifications

Voltage Ratings: Primary voltage ranges from 2.4 kV to 34.5 kV, with secondary outputs of 208Y/120V, 480Y/277V, or 600V (three-phase).

Capacity: Available from 75 kVA to 5000 kVA, supporting industrial machinery, data centers, and large-scale renewable energy systems.

Cooling Systems: Oil-immersed (ONAN/ONAF) or dry-type (ventilated or cast resin) configurations, compliant with IEEE C57.12.25 temperature rise limits.

Efficiency: Meets or exceeds IEEE C57.12.00, IEC 60076, and NEMA ST-20 standards.

Applications

Industrial Facilities: Powers manufacturing plants, refineries, and mining operations with high, continuous load demands.

Commercial Complexes: Supplies energy to shopping malls, office towers, and data centers requiring stable three-phase power.

Utility Grids: Integrates with underground distribution networks in urban and suburban areas, reducing visual impact.

Renewable Energy: Connects solar farms, wind turbines, or battery storage systems to the grid for scalable energy distribution.

Public Infrastructure: Supports hospitals, airports, and universities with reliable, low-maintenance power.

Advantages Over Alternatives

Space-Saving Design: Eliminates overhead lines and pole-mounted infrastructure, optimizing land use in congested areas.

Scalability: Modular configurations allow capacity upgrades to match evolving energy needs.

Enhanced Safety: Lockable, grounded enclosures prevent unauthorized access and reduce electrocution risks.

Reduced Downtime: Front-access panels and predictive maintenance tools simplify servicing and repairs.

Installation & Maintenance

Installation: Mounted on reinforced concrete pads with proper drainage and ventilation. Pre-assembled units minimize on-site labor and commissioning time.

Accessibility: Designed for easy access to bushings, cables, and monitoring systems without disassembling the enclosure.

Monitoring: Smart models feature IoT sensors for real-time tracking of load balance, oil quality (if applicable), and thermal performance.

Lifespan: Built for 30–40 years of service with routine inspections (oil testing, insulation resistance checks, and thermal imaging).

Compliance & Sustainability

Complies with IEEE C57.12.25, IEC 60076, and NEMA ST-20 standards.

Eco-friendly options include dry-type transformers (no oil), recyclable enclosure materials, and biodegradable insulating fluids.

The three-phase pad-mounted transformer is a versatile, high-performance solution for modern power distribution challenges. Its ability to deliver efficient, reliable three-phase power in compact, secure enclosures makes it indispensable for industries, utilities, and urban planners prioritizing safety, sustainability, and operational efficiency. By combining rugged construction with smart monitoring capabilities, it ensures seamless energy delivery for today’s high-demand applications while supporting future grid innovations.

1. Core Materials and Winding Design

Core Materials

Amorphous Alloy Cores: Utilize low-loss amorphous metal alloys, achieving 70–80% lower iron losses compared to traditional silicon steel. Their near-zero magnetostriction minimizes noise and vibration, critical for urban and industrial environments.

Graded Silicon Steel Laminations: High-permeability, cold-rolled silicon steel with laser-cut or step-lapped joints reduces eddy current losses, enhancing efficiency (up to 98.5%) and thermal stability for continuous high-load operation.

Winding Design

Foil Windings with Interleaved Conductors: Copper or aluminum foil windings reduce leakage flux and short-circuit forces, improving overload resilience. Multi-layer interleaving optimizes current distribution.

Layered Litz Wire Windings: Multi-strand Litz wire minimizes skin and proximity effects, ensuring uniform current density and reduced AC resistance in high-voltage applications (e.g., 11kV–33kV).

Compact Triple-Limb Core Design: Symmetrical three-phase core configuration reduces flux imbalance, enhancing efficiency and minimizing zero-sequence losses.

2. Insulation Systems

Oil-Immersed Paper-Oil Composite: Premium insulating oils (e.g., ester-based fluids) combined with Nomex paper provide exceptional dielectric strength (up to 300 kV BIL) and fire resistance, ideal for harsh environments.

Epoxy Resin Casting (Dry-Type): Vacuum-pressure impregnation (VPI) with Class H epoxy resin ensures UL-certified fire safety, moisture resistance, and dielectric withstand for medium-voltage applications (10kV–35kV).

Nano-Enhanced Insulation: Silica-filled epoxy composites improve partial discharge resistance, extending service life in humid, polluted, or coastal areas.

3. Thermal Management

Oil-Natural Air-Cooling (ONAN): Passive cooling via finned radiators and oil circulation for continuous operation at rated loads, ideal for remote substations.

Forced Air Cooling (OFAF): Temperature-controlled fans enhance heat dissipation during peak loads, maintaining efficiency up to 120% of nameplate capacity.

Smart Thermal Monitoring: Embedded temperature sensors and IoT-enabled systems trigger alarms, load shedding, or fan activation to prevent overheating and insulation degradation.

4. Structural Design and Protection

Modular and Robust Construction

Heavy-Duty Pad Base: Reinforced concrete or polymer pads ensure stability, theft resistance, and vibration damping for long-term reliability.

IP68/IP69K Ratings: Hermetic enclosures with EPDM gaskets and stainless-steel hardware protect against water, dust, and mechanical impacts (e.g., flooding, debris).

Anti-Corrosion Coatings: Hot-dip galvanized steel or aluminum enclosures with polyurethane/powder coatings resist UV degradation, salt spray, and industrial pollutants.

Safety and Reliability Features

Surge Protection Systems: Integrated zinc oxide arresters (MOA) and surge capacitors suppress lightning-induced transients and switching surges.

Pressure Relief Valves: Automatically vent gases during internal faults (e.g., short circuits), preventing catastrophic tank rupture.

Short-Circuit Withstand Design: Axial/radial winding reinforcement and finite element analysis (FEA)-optimized frames endure fault currents up to 50kA asymmetrical.

5. Advanced Functionalities

Condition Monitoring Systems (CMS): Embedded sensors track oil temperature, load levels, partial discharge, and dissolved gas analysis (DGA), transmitting data to SCADA for predictive maintenance.

On-Load Tap Changers (OLTC): AI-driven tap adjustment optimizes voltage regulation under fluctuating grid conditions, reducing energy losses.

Eco-Friendly Innovations: Bio-based insulating oils and recyclable polymer components align with sustainability goals (e.g., IEC 62721 compliance).

Key Applications and Future Trends

Industrial Parks: High-capacity units (500kVA–5MVA) power heavy machinery and continuous processes.

Renewable Energy Integration: Ideal for wind/solar farms and microgrids, supporting bidirectional power flow.

Future Advancements:

Solid-State Transformers (SSTs): Enable grid flexibility via DC-DC conversion and real-time power quality management.

Self-Healing Insulation: Nanocomposite materials autonomously repair minor dielectric breakdowns.

Summary

Three-Phase Pad-Mounted Transformers excel through low-loss amorphous cores, advanced thermal management, modular designs, and multi-layered safety systems. Their combination of efficiency, scalability, and resilience makes them indispensable for modern power distribution, with innovations like solid-state technology paving the way for smarter, greener grids.

(1).webp?x-oss-process=image/resize)