Single Phase Pad Mouted Transformer

LED LIGHTING GROUP

Single Phase Pad Mouted Transformer

◆ Definition

Single-phase pad-mounted transformer is the type with a clamshell cabinet for ease to opening and uninhibited access to connection. Versatility of the design allows for various protectionandswitching configuration. It provides multi-service options while meeting the reliability and safety requirements of any distribution system. It has various ratings and with wide range of advanced configurations to meet customer's demands.

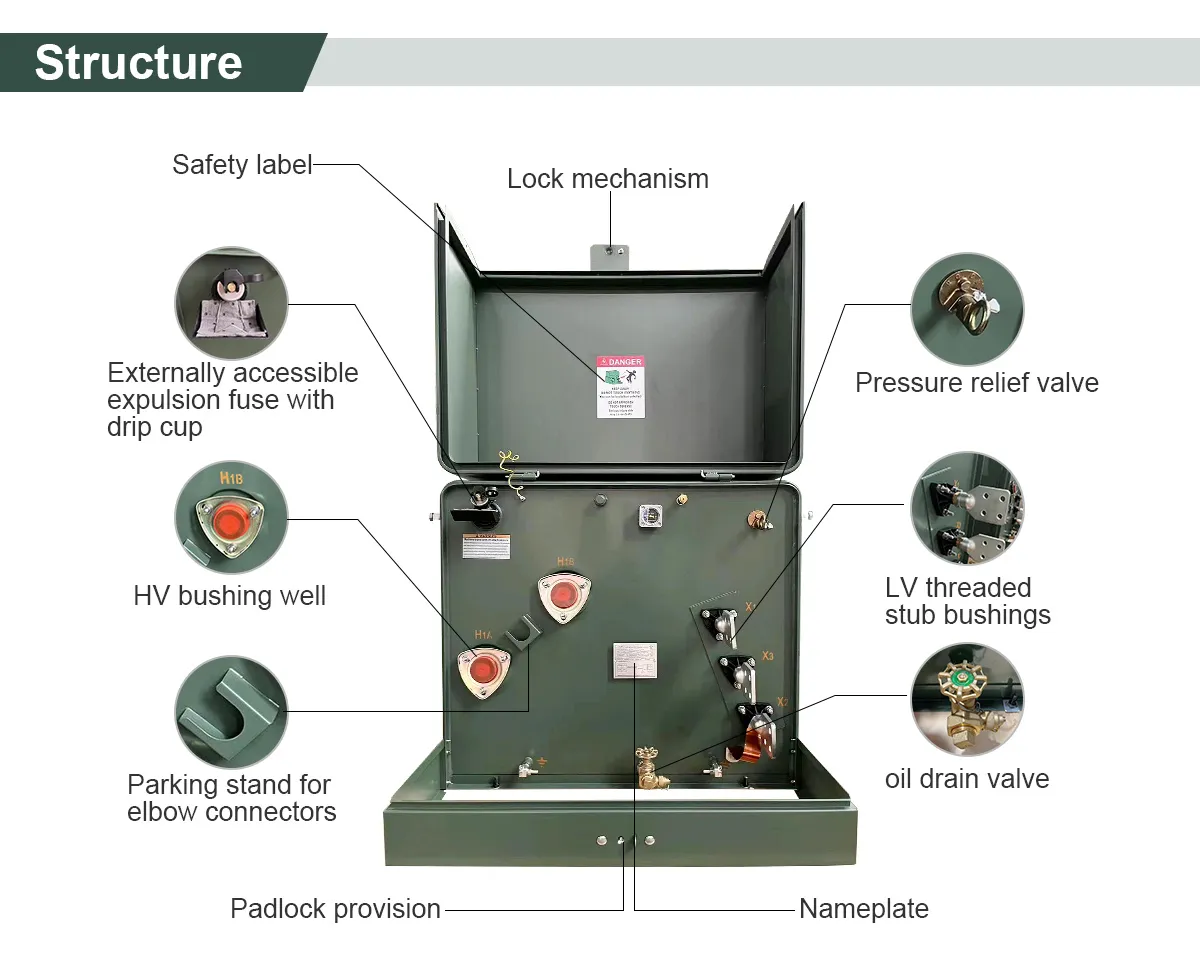

◆ Structure

◆ Specificationof10kvato167kva

| Capacity (KVA) | High Voltage (V) | Tapping Ranges | Low Voltage (V) | Loss (W) | Dimension (mm) | DOE2016 Efficiency | |||

|---|---|---|---|---|---|---|---|---|---|

| No-load Loss (W) | On-load Loss (W) | W | D | H | |||||

| 15 | 2400 4160 7200 12000 13200 13800 19920 24940 34500 |

±2×2.5% | 110 120 208 240 277 347 415 480 690 |

60 80 100 120 130 150 |

330 370 450 620 850 1150 |

610 610 610 610 610 740 |

740 740 760 810 960 940 |

840 840 840 840 840 840 |

98.82 |

| 25 | 98.95 | ||||||||

| 37.5 | 99.05 | ||||||||

| 50 | 99.11 | ||||||||

| 75 | 99.19 | ||||||||

| 100 | 99.25 | ||||||||

| 167 | 99.33 | ||||||||

| 250 | 99.39 | ||||||||

| 333 | 99.43 | ||||||||

| 500 | 99.49 | ||||||||

Efficient Outdoor Single-Phase Pad-Mounted Transformers

A single-phase pad-mounted transformer is a ground-level electrical distribution device designed to step down medium-voltage power to usable low-voltage levels for residential, commercial, and light industrial applications. Encased in a robust, tamper-resistant enclosure, these transformers are widely deployed in urban, suburban, and semi-urban areas where aesthetics, safety, and space optimization are priorities.

Key Features

Compact & Secure Design: Housed in weatherproof, lockable enclosures (typically corrosion-resistant steel or aluminum), these units protect internal components from vandalism, weather, and accidental contact.

High Efficiency: Utilizes premium core materials (e.g., amorphous steel or grain-oriented silicon steel) and precision-engineered windings to minimize energy losses, meeting DOE 2016 and IEC 60076 efficiency standards.

Low Noise Operation: Engineered with noise-dampening materials and optimized magnetic circuits, ideal for noise-sensitive areas like neighborhoods and hospitals.

Low Maintenance: Sealed construction (oil-filled or dry-type) prevents contamination, while advanced monitoring systems enable predictive maintenance.

Safety Compliance: Features grounded enclosures, fault indicators, pressure-relief devices, and arc-resistant designs. Oil-filled models use fire-resistant or biodegradable fluids.

Technical Specifications

Voltage Ratings: Primary voltage ranges from 2.4 kV to 34.5 kV, with secondary outputs of 120/240V or 230/400V (single-phase).

Capacity: Available from 25 kVA to 500 kVA, supporting diverse load demands, including clustered residential complexes and small commercial facilities.

Cooling: Oil-immersed (ONAN) or dry-type (ventilated or encapsulated) configurations, with temperature rise limits per IEEE C57.12.25.

Protection Rating: Enclosures rated IP55 or higher for dust and water resistance.

Applications

Urban Distribution: Ideal for underground power networks in cities, suburbs, and planned communities.

Commercial Zones: Powers shopping centers, office parks, and mixed-use developments with minimal visual impact.

Renewable Energy Systems: Integrates with solar/wind installations or microgrids for localized energy distribution.

Critical Infrastructure: Supports hospitals, schools, and data centers requiring reliable, low-noise power.

Advantages Over Alternatives

Space Efficiency: Eliminates the need for poles, freeing up aerial space and reducing visual clutter.

Enhanced Safety: Ground-level enclosures prevent public access, reducing electrocution risks.

Scalability: Modular designs allow easy capacity upgrades to match growing energy demands.

Durability: Corrosion-resistant materials and robust construction ensure longevity in harsh environments.

Installation & Maintenance

Installation: Mounted on concrete pads with proper ventilation and drainage. Requires minimal site preparation compared to underground vaults.

Accessibility: Front-access design simplifies maintenance, inspections, and repairs without disassembling the unit.

Monitoring: Advanced models include IoT-enabled sensors for real-time tracking of load, oil quality (if applicable), and temperature.

Lifespan: Designed for 30–40 years of service with routine inspections (e.g., oil testing, bushing checks, and thermal imaging).

Compliance & Sustainability

Complies with IEEE C57.12.25, IEC 60076, and NEMA ST-20 standards.

Eco-friendly options include dry-type transformers (no oil), recyclable enclosure materials, and biodegradable insulating fluids.

The single-phase pad-mounted transformer is a versatile, safe, and efficient solution for modern power distribution networks. Its ground-level installation, combined with robust security and low environmental impact, makes it indispensable for utilities and developers prioritizing safety, aesthetics, and operational reliability. Whether powering urban neighborhoods or renewable energy hubs, this transformer balances performance with sustainability.

Core Materials

Amorphous Alloy Cores: Utilize low-loss amorphous metal alloys, offering 70–80% lower iron losses compared to traditional silicon steel. Their high permeability and near-zero magnetostriction reduce noise and vibration, ideal for residential areas.

Graded Silicon Steel: Advanced cold-rolled silicon steel with laser-cut laminations minimizes air gaps and eddy current losses, improving efficiency (up to 98%) and thermal stability.

Winding Design

Foil Windings: Copper or aluminum foil windings reduce leakage flux and short-circuit forces, enhancing overload resilience.

Layered Litz Wire: Multi-strand Litz wire windings mitigate skin and proximity effects, optimizing current distribution and efficiency.

Compact Coil Arrangement: Axial compression and resin-impregnation techniques enhance mechanical strength and thermal conductivity.

2. Insulation Systems

Epoxy Resin Casting: Dry-type transformers use vacuum-pressure impregnation (VPI) with high-temperature epoxy resin (Class H insulation), providing UL-certified fire resistance and moisture resistance.

Oil-Immersed Insulation: For high-capacity units, premium insulating oils (e.g., ester-based fluids) combined with Nomex paper offer fire safety and dielectric strength up to 200 kV.

Nano-Enhanced Insulation: Silica-filled epoxy composites improve partial discharge resistance, extending service life in humid or polluted environments.

3. Thermal Management

Oil-Natural Air-Cooling: Oil circulation and finned radiators provide passive cooling for continuous high-load operation.

Forced Air Cooling: Temperature-controlled fans activate when oil temperatures exceed thresholds, maintaining safe operating limits.

Smart Thermal Sensors: Embedded thermistors and IoT-enabled monitoring systems trigger alarms or load-shedding protocols to prevent overheating.

4. Structural Design and Protection

Modular and Compact Design

Base-Mounted Enclosure: Robust concrete or polymer pads ensure stability and theft resistance.

IP68-Rated Sealing: Hermetic enclosures with EPDM gaskets protect against water, dust, and rodent intrusion, even in flood-prone areas.

Anti-Corrosion Coatings: Hot-dip galvanized steel or aluminum enclosures with polyurethane powder coatings resist UV degradation and salt spray.

Safety Features

Internal Surge Protection: Zinc oxide surge arresters (MOA) and surge capacitors suppress lightning-induced transients.

Pressure Relief Valves: Automatically vent gases during internal faults, preventing explosive failures.

Tamper-Proof Design: Lockable access panels and GPS-enabled anti-theft tags deter vandalism.

5. Advanced Functionalities

Condition Monitoring Systems: Built-in sensors track oil temperature, load levels, and partial discharge, transmitting data to SCADA systems for predictive maintenance.

Energy Efficiency Optimization: AI-driven algorithms dynamically adjust tap changers to minimize losses under varying load conditions.

Eco-Friendly Designs: Bio-based insulating oils and recyclable polymer components align with sustainability goals.

Key Applications and Future Trends

Ideal for urban substations, renewable energy integration (e.g., solar farms), and industrial parks.

Future advancements include solid-state transformers (SSTs) for grid flexibility and self-healing insulation materials to reduce downtime.

Summary

Single-Phase Pad-Mounted Transformers excel through low-loss amorphous cores, smart thermal management, modular designs, and multi-layered protection systems. Their blend of efficiency, safety, and adaptability makes them a cornerstone of modern distribution networks, with ongoing innovations driving greener, smarter grids.

(1).webp?x-oss-process=image/resize)